What Is A Blister Pack

A blister pack is a type of packaging that consists of a pre-formed plastic pocket or cavity (the "blister") and a backing material (typically foil or cardboard). These packs are widely used in:

- * Pharmaceutical industry (80% of unit-dose medications)

- * Consumer goods (small hardware, electronics components)

- * Food industry (single-serving items)

Key Components:

- 1. Cavity/Blister: Usually made of PVC, PVDC, or COC plastics

- 2. Lidding Material: Aluminum foil, paper, or plastic films

- 3. Tamper-evident features: Critical for medication safety

Why Blister Packaging Dominates Medication Delivery

- Dosage Control: Each cavity contains one dose (critical for elderly patients)

- Moisture Protection: Foil backing provides superior barrier properties

- Portability: Compact design ideal for travel medications

- Medication Adherence: Clear visible tracking of doses taken

- Child Resistance: Meets CPSC safety standards (when properly designed)

Industry Insight: The global blister pack medication market is projected to reach $19.8 billion by 2027 (CAGR 6.2%) - Source: Grand View Research

Types of Medicine Blister Packs

| Type | Description | Common Uses |

|---|---|---|

| Push-Through | Aluminum lidding | Tablets, capsules |

| Peel-Push | Peelable lidding | Large tablets |

| Child-Resistant | Special opening mechanism | Pediatric safety |

| Cold-Form | Deep-drawn aluminum blisters | Oxygen-sensitive drugs |

How Blister Packing Machines Work

- 1. Forming Station: Heated plastic sheet formed into cavities

- 2. Product Loading: Automated placement of tablets/capsules

- 3. Lidding: Sealing with backing material

- 4. Cutting: Separation into individual units or strips

Technical Specs:

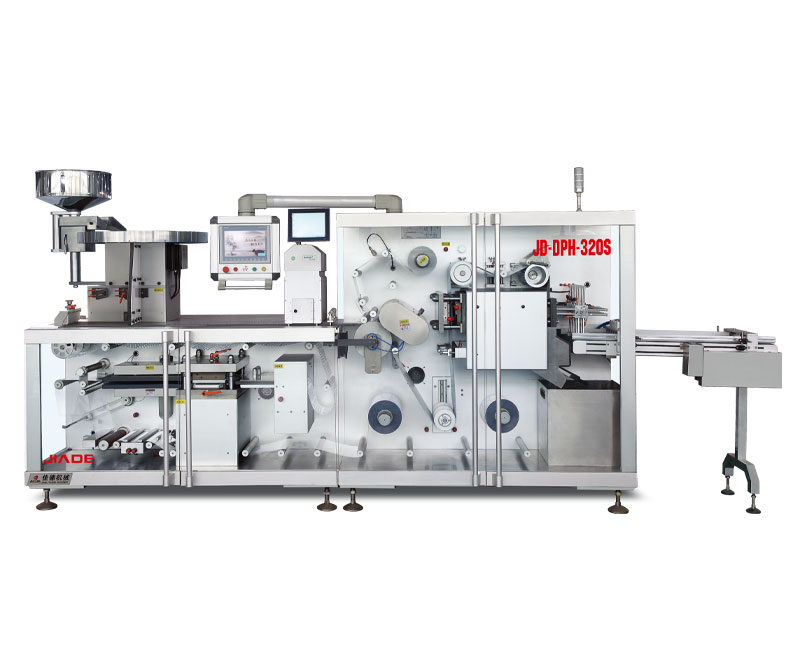

JD-DPH-320/320S is a high-speed blister packing machine that integrates flat forming and roller hot sealing. It is suitable for packing sugar-coated tablets, plain tablets, hard capsules, soft capsules, special-shaped tablets and other drugs of various specifications. It can also be used for packing of hardware, electronic components, medical instruments and food whose shapes are similar to those of the above-mentioned drugs.

- * Speed: Up to 150 Stoke/min (or 9.5 m)

- * Accuracy: ≤0.5% error rate in modern machines

- * Formats: Can handle various blister sizes (10mm to 50mm common)

Emerging Trends in Blister Packaging

- Smart Blister Packs

- *Embedded NFC chips for medication tracking

- *Time-temperature indicators for vaccine packaging

- *Augmented reality packaging for patient education

- Sustainability Innovations

- *Recyclable materials: Using rPET or PLA bioplastics

- *Reduced material use: Thinner but equally protective films

- *Return programs for blister pack recycling

Choosing the Right Blister Pack Solution

- For Pharmacies/Dispensaries:

- 1.Verify compliance with local regulations

- 2.Consider patient demographics (elderly vs. pediatric)

- 3.Evaluate drug characteristics (hygroscopicity, light sensitivity)

- For Manufacturers:

- 1.Machine versatility for different product lines

- 2.Serialization capabilities for track-and-trace

- 3.Validation requirements for FDA/EU markets

Future Outlook: The Next Decade

- *Personalized medicine: Small batch manufacturing

- *IoT integration: Real-time adherence monitoring

- *3D printed blisters: On-demand packaging

- *Anti-counterfeiting: Advanced holographic seals

Pro Tip: When searching for blister pack packaging machine for meds, look for ISO 15378 certification - the gold standard for pharmaceutical primary packaging materials.