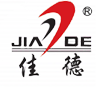

JD-RFW-300C/JDZ-260

Automatic High Speed Double Pillow Packing-Cartoning Production Line

Applications: It suitable for kinds of capsule, tablet, sugar-coated tablet, pill, abnormity tablet, chocolate bean, chewing gum and so on small food product blister packing and pillow packing and encasing.

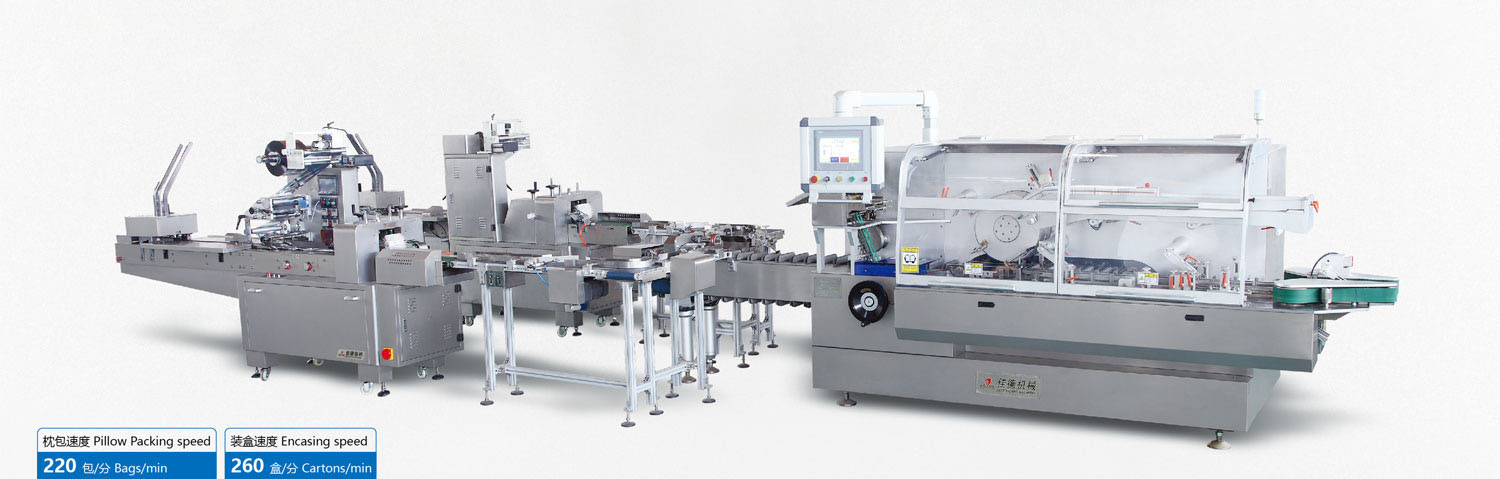

JD-RFW-300C/JDZ-120

Automatic Pillow Packing-Cartoning Production Line

Applications: This packing production line is suitable for pillow package bag inserting to carton which automaticaly link to cartoning machine. Online can automatic finish product feeding (such as blister), detecting,aluminum film packing, rejecting for lack of product, pillow package bag automatic middle transferring and feeding, leaflet folding, carton forming, product inserting, batch number printing, carton flap sealing, waste product rejecting, finished product output, product counting and so on.

JD-DPH-260/JDZ-260

Automatic Blister Packing/cartoning Production Line

Applications: The production line is suitable for pillow type bag full automatic pillow packing-cartoning-Overwrapping linkage production line.

Industry Classification

Pharmaceutical Packaging

- • Capsules

- • Blisters and Cartridges

Food Packaging