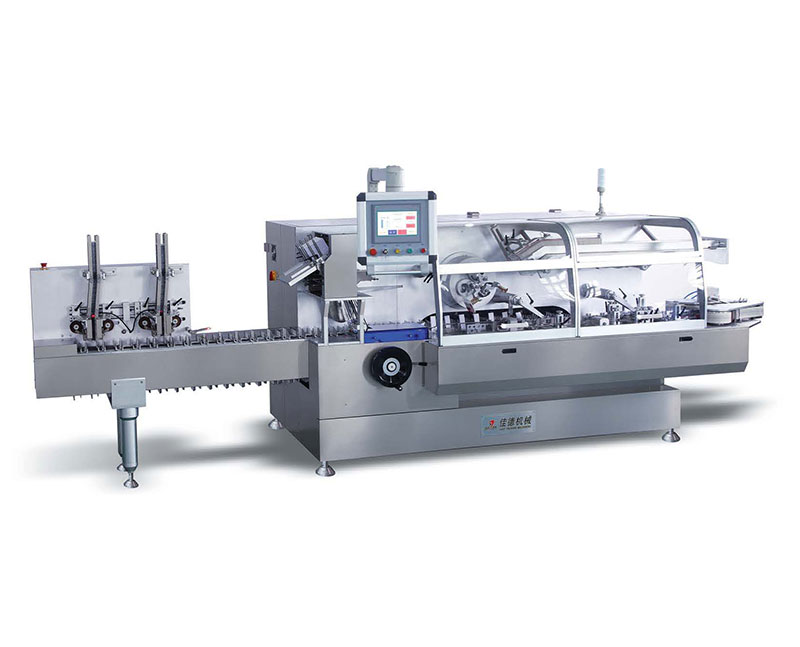

JD-DPH-320s+JDZ-600s

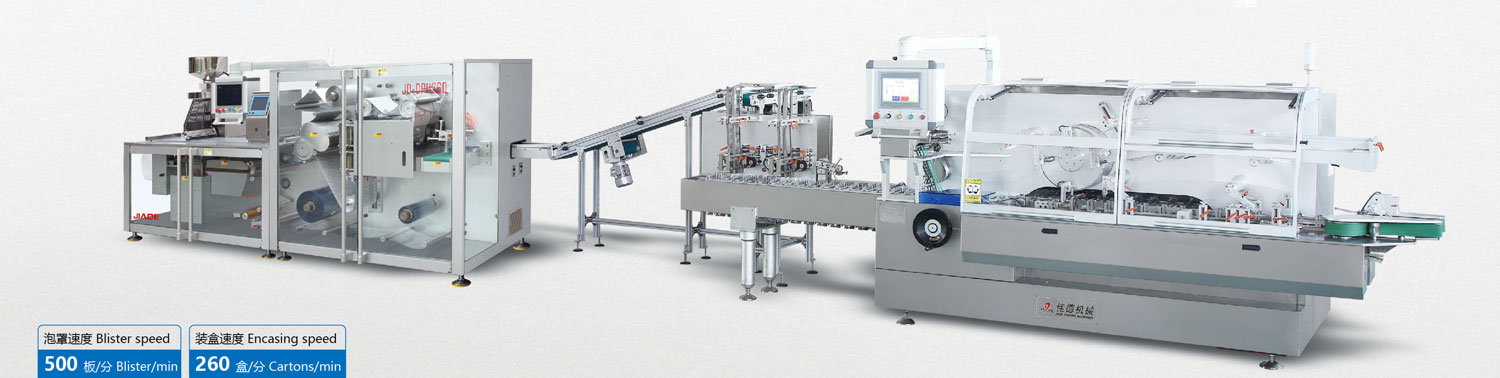

JD-DPH-260/JDZ-450/JD-K760

Automatic Blister Packing/Cartoning/Film Bundling Production Line

Applications: Automatic blister packing/cartoning/film bundling production line intergrates the production of blister forming, filling, detection, sealing, cutting, blister cartoning, rejection, carton film bundling for pharmaceutical, food, medical apparatus, instruments, health care products, electronic components, etc.

JD-DPH-260/JDZ-260

Automatic Blister Packing/cartoning Production Line

Applications: It suitable for kinds of capsule, tablet, sugar-coated tablet, pill, abnormity tablet, chocolate bean, chewing gum and so on small food product blister packing and encasing

Industry Classification

Pharmaceutical Packaging

- • Capsules

- • Blisters and Cartridges

Food Packaging

Personal Care Packaging