Cartoning speed: Up to 450 Cartons/min

Suitable for: Blister Packs, Bottles, Tubes, Strips, Sachets, and Pouches

Cartoning speed: Up to 600 Cartons/min

Suitable for: Blister Packs, Bottles, Tubes, Strips, Sachets, and Pouches

Cartoning speed: Up to 320 Cartons/min

Suitable for: Blister Packs, Bottles, Tubes, Strips, Sachets, and Pouches

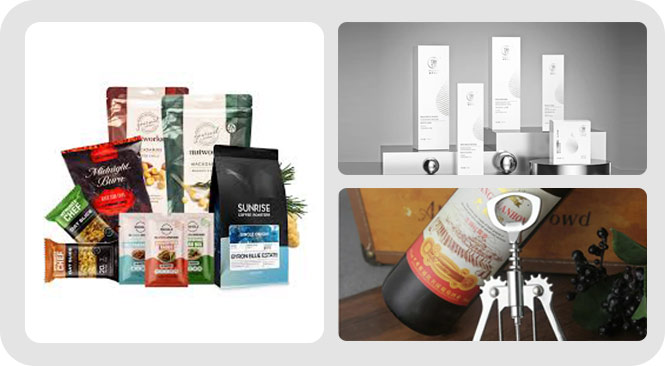

Offer standalone equipment or complete packaging lines tailored to diverse customer needs.

Capable of handling special cases like inclined boxes, hexagonal boxes, and other non-standard formats, ensuring packaging quality and efficiency.

Provide operational manuals, maintenance guides, 3Q documents (Quality, Cost, Delivery), and installation/inspection procedures for smooth operation and customer satisfaction.