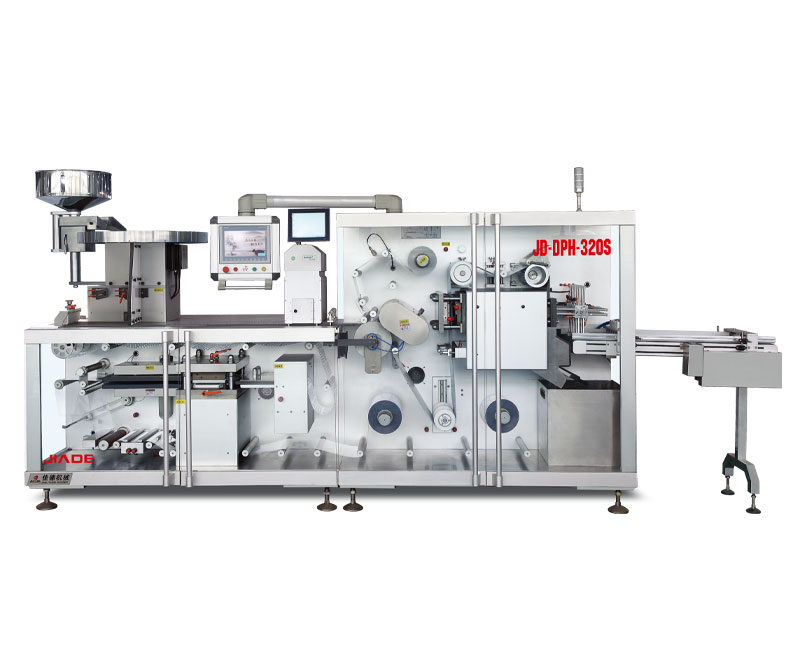

Max. Punch Frequency: 150 Stoke/min (or 9.5 m)

Max. Forming area(LxW): 180x310mm

Machine dimension(LxWxH): 3550mmx1100mmx1950mm

Max. Punch Frequency: 150 Stoke/min (or 9.5 m)

Max. Forming area(LxW): 180x250mm

Machine dimension(LxWxH): 4550mmx1250mmx2115mm

Cutting speed: 20-50stroke/min

Max. blister forming size: 240*150*14mm

Machine dimension(LxWxH): 3700mmx720mmx1550mm

Offer standalone equipment or complete packaging lines tailored to diverse customer needs.

Capable of handling special cases like inclined boxes, hexagonal boxes, and other non-standard formats, ensuring packaging quality and efficiency.

Provide operational manuals, maintenance guides, 3Q documents (Quality, Cost, Delivery), and installation/inspection procedures for smooth operation and customer satisfaction.