What is Blister Packaging Used for?

If you’re a manufacturer in pharmaceuticals, food, or consumer goods, you’ve likely seen blister packaging everywhere—but do you know why it’s one of the most trusted packaging solutions globally? How does investing in a reliable blister packing machine amplify its benefits? Let’s break down the core uses of blister packaging, the industries that depend on it, and why the right equipment makes all the difference.

The Core Goals of Blister Packaging—Beyond Just “Wrapping”

At its heart, blister packaging is designed to solve three critical challenges for manufacturers: protection, visibility, and compliance. Unlike traditional boxes or bags, its rigid plastic “blister” (the concave compartment) and sealed backing (often foil, paper, or plastic) create a barrier that:

- Shields products from damage: Fragile items—like pharmaceutical tablets, small electronics (e.g., batteries or earbuds), or delicate snacks—stay intact during shipping and storage, even with minor impacts.

- Blocks moisture, dust, and contaminants: For industries like pharmaceuticals and food, this is non-negotiable. Blister packs prevent spoilage, maintain product potency (think: vitamins or medications), and extend shelf life.

- Offers clear product visibility: Customers and retailers can see the exact product inside without opening the package, which boosts trust (no “hidden surprises”) and helps with inventory checks.

- Ensures portion control and safety: Single-serve blister packs (e.g., one pill per blister, one candy per compartment) reduce waste and prevent tampering—critical for pharmaceuticals (where dosage accuracy matters) and food (where freshness per serving is key).

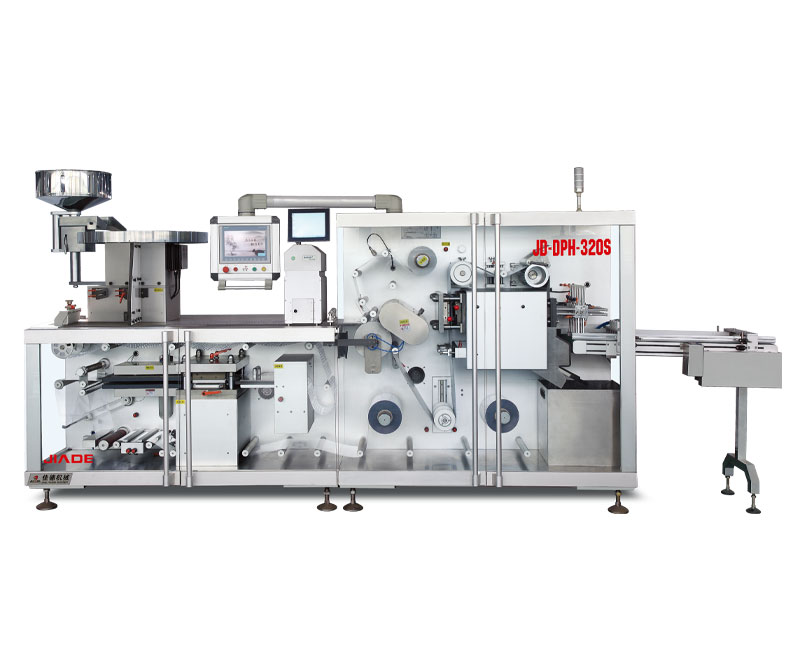

To achieve these goals consistently, though, you need a blister packing machine that’s calibrated to your product’s size, material, and industry standards. A well-designed machine will adapt to different product specs, maintain strict sealing quality, and align with global compliance rules—turning blister packaging from a basic tool into a strategic asset.

Top Industries Using Blister Packaging (And Their Specific Needs)

Blister packaging isn’t one-size-fits-all—and neither are the machines that produce it. Let’s look at the sectors that rely on it most, and how a tailored blister packing machine addresses their unique requirements:

Pharmaceuticals: Compliance and Precision First

Pharmaceutical manufacturers are the biggest users of blister packaging, and for good reason: regulatory bodies (like the FDA or EMA) require packaging that’s tamper-evident, moisture-resistant, and traceable. Blister packs check all these boxes—and a pharmaceutical-grade blister packing machine takes it further by:

- Meeting GMP (Good Manufacturing Practices) standards, ensuring no cross-contamination during production.

- Creating consistent seals that prevent air or moisture from reaching medications (critical for preserving drug efficacy).

- Integrating with downstream equipment (e.g., cartoning machines) for a seamless “blister-to-box” workflow, reducing manual labor and errors.

Many pharmaceutical clients report cutting packaging errors by 50% after switching to a purpose-built blister packing machine—all while staying compliant with strict industry audits.

Food and Beverage: Freshness and Convenience

For food manufacturers, blister packaging is all about keeping products fresh and easy to use. Think: single-serve cheese slices, energy bars, or frozen appetizers. A food-grade blister packing machine needs to:

- Use food-safe materials that don’t leach chemicals into products.

- Adjust to different product textures—from soft snacks to hard candies—without damaging them.

- Operate at high speeds to keep up with food production volumes.

Top-tier blister packing machine excel here: their adjustable sealing temperature and speed settings let manufacturers switch between products in minutes, no lengthy retooling required.

Consumer Electronics and Hardware: Protection for Small Parts

Small electronic components (earbuds, USB drives) or hardware (screws, nails) need packaging that prevents scratches, tangles, or loss. Blister packs keep these items organized and visible—and a durable blister packing machine ensures the plastic blister is thick enough to resist cracking, even during transit. Leading machines are often chosen for this sector because of their ability to handle rigid or flexible plastics, depending on the product’s needs.

Why Your Blister Packing Machine Matters as Much as the Packaging Itself

Even the best blister packaging design fails if your machine can’t execute it reliably. A low-quality machine might produce inconsistent seals (leading to product spoilage), jam frequently (slowing down production), or fail to meet industry standards (costing you compliance fines).

A reliable blister packing machine solves these pain points by focusing on:

- Precision: Servo motor control ensures every blister is formed and sealed evenly, reducing waste (no more misaligned packs).

- Versatility: It works with multiple materials (PVC, PET, aluminum foil) and product sizes, so you don’t need a separate machine for each product line.

- Compliance: It’s CE and ISO 9001 certified, plus ready to integrate with 3Q documentation (IQ/OQ/PQ) for pharmaceutical clients—saving you time on audit prep.

- Support: Quality manufacturers offer full lifecycle support, from installation to maintenance, so your machine stays operational (no costly downtime).

In short, a good blister packing machine isn’t just an expense—it’s an investment in consistent quality, faster production, and long-term compliance.

Ready to Optimize Your Blister Packaging Process?

If you’re tired of dealing with inconsistent blister packs, compliance headaches, or slow production lines, it’s time to invest in a blister packing machine that’s built for your industry. JIADE Engineering’s blister packing machine isn’t just a piece of equipment—it’s a solution tailored to pharmaceuticals, food, and consumer goods manufacturers who need reliability, speed, and compliance. Reach out to JIADE today to discuss your product’s unique needs.

This article contains approximately 30% AI-assisted content, with core industry insights, product details, and practical advice curated by human experts in packaging machinery.