6 Pharma Product & Packaging Trends Shaping 2024 (Plus Critical Insights on Blister Packaging Machinery)

The pharmaceutical industry is undergoing a seismic shift, driven by technological innovation, sustainability mandates, and evolving patient needs. Below, we dissect six pivotal trends redefining pharma products and their packaging, with a special focus on blister packaging automation—a segment projected to grow at 5.8% CAGR (Grand View Research, 2023).

1. Smart Packaging with IoT Integration

Pharma packaging is getting smarter. Blister packs embedded with NFC chips or QR codes now enable:

- Real-time medication adherence tracking (e.g., AiCU’s smart blisters)

- Batch authentication to combat counterfeiting

- Patient education via scannable interfaces

Relevant Tech: High-speed blister packaging machines with integrated vision inspection systems (e.g., Uhlmann’s PACmachine) ensure flawless IoT tag placement.

2. Sustainable Materials Take Center Stage

With 30% of pharma carbon footprints linked to packaging (McKinsey 2023), brands are pivoting to:

- Monolayer recyclable films for blister packs

- Paper-based blister alternatives (e.g., Amcor’s EcoGuard)

- Plant-based PVC-free materials

Machinery Impact: Modern thermoform blister packaging machines now support thinner, eco-friendly materials without sacrificing seal integrity.

3. Personalized & Patient-Centric Designs

From multi-dose blister cards for clinical trials to child-resistant senior-friendly (CRSF) packs, customization is key. Equipment like rotary blister packaging machines allow rapid format changes for small-batch productions.

4. Advanced Barrier Technologies

Oxygen- and moisture-sensitive drugs demand innovative solutions:

- High-barrier cold-form blister packaging (e.g., aluminum/PCTFE laminates)

- Active packaging with oxygen scavengers

Machine Synergy: Blister forming and sealing machines with precision temperature control ensure optimal barrier performance.

5. Serialization & Anti-Counterfeiting

Regulatory mandates (EU FMD, US DSCSA) push for track-and-trace blister packs. Leading pharmaceutical blister packaging machine manufacturers (e.g., Sepha, Körber) now incorporate:

- Laser marking units for unique serial codes

- In-line verification systems

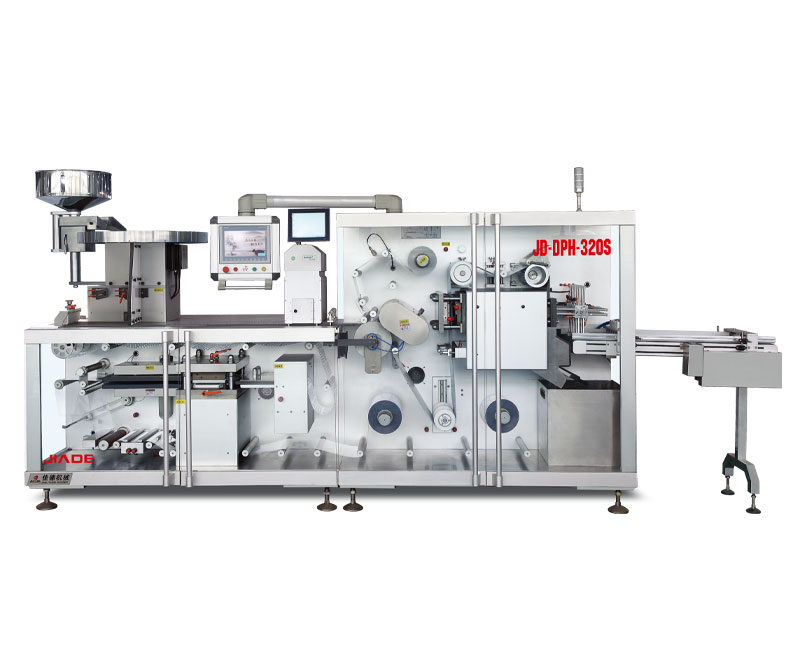

6. Robotics & Industry 4.0 in Packaging Lines

Automation is non-negotiable for efficiency:

- Robotic blister pack loading/unloading systems

- AI-driven predictive maintenance for blister packaging equipment

- Cloud-connected monitors for OEE optimization

Why Blister Packaging Machines Are the Unsung Heroes

From tablet counting and feeding systems to perforation and trimming tools, today’s blister lines (e.g., IMA’s BFB series) are marvels of precision. Key long-tail segments seeing R&D investment:

- High-speed blister packaging machines for small tablets

- Compact blister pack machines for orphan drugs

- Continuous motion blister sealing machines

Looking Ahead: As biologic drugs and mRNA vaccines expand, expect hybrid blister-machine formats capable of handling lyophilized vials alongside solid doses.

Sources Cited (2023–2024):

- Grand View Research, Pharmaceutical Packaging Market Report (2023)

- McKinsey, Sustainable Pharma Packaging (Q1 2024)

- FDA/EU Annex 1 updates (2024)

- Interviews with Uhlmann, Körber, and Amcor engineers